This blog is part of a series on designing a demand driven operating model.

1. What are Decoupling Points?

2. What are Control Points?

3. Protecting Decoupling and Control Points

A. Stock Buffers (Decoupling Points)

B. Time Buffers (Control Points)

C. Capacity Buffers (Decoupling and Control Points)

Becoming Demand Driven

In the modern manufacturing industry that experiences ever-increasing complexity, one of organizations’ biggest hopes for minimizing variability, maximizing flow, and achieving long-term competitive success is becoming demand driven.

As Debra Smith and Chad Smith state in their book, Demand Driven Performance: “Demand driven strategy is about dramatic lead-time compression and the alignment of efforts to respond to market requirements. This includes careful synchronization of planning, scheduling, and execution with actual consumption.” The idea is that organizations position themselves and their operations to be able to respond to customers and the environment in the most agile way possible, and with the least waste (of time, money, and other resources) possible.

Demand Driven Operating Model

Part of becoming demand driven, aside from understanding the growing complexities of the manufacturing industry and the implications of flow and variability, is designing a demand driven operating model.

We’ve already covered the first two steps of the design process, placing decoupling points and control points, and this blog will discuss the big ideas behind the third step of the process, which is protecting decoupling and control points with buffers, and dive into what time buffers are. While these blogs will provide a useful jumping-off point, oftentimes the most effective way to successfully create a demand driven operating model for your organization is working with a trained professional who understands the process deeply and can help guide you through it. If you’re interested in learning more or beginning the process, members of our team at Repathis, are certified as Demand Driven Leader Professionals, meaning we have resources certified to analyze and evaluate organizations using the demand driven operating model and demand driven S&OP principles. Contact us here if you’d like to learn more about designing a demand driven operating model and applying demand driven principles.

Let’s tackle the third step in designing a demand driven operating model: protecting decoupling and control points.

How to Protect Decoupling and Control Points? Buffers.

Buffers are needed to protect decoupling and control points from accumulated variability. By placing buffers, decoupling points and control points can dynamically adjust to variability and more effectively protect flow.

There are three types of buffers used to protect decoupling and control points. We've already covered the stock buffer, which specifically protects decoupling points and is considered integral to a well-functioning demand driven operating model. Now, we'll turn our attention to time buffers, which protect control points.

Demand Driven Time Buffers

“Demand driven time buffers are planned amounts of time inserted in the product routing in order to cushion a control point schedule from disruption.” These buffers are important because they protect control points from disruption, which protects all other resource and area schedules that are determined by control points.

The size of demand driven time buffers are based on the reliability of all resources that funnel into the respective control point. The less reliable the string of resources is for that control point, the larger the time buffer will be.

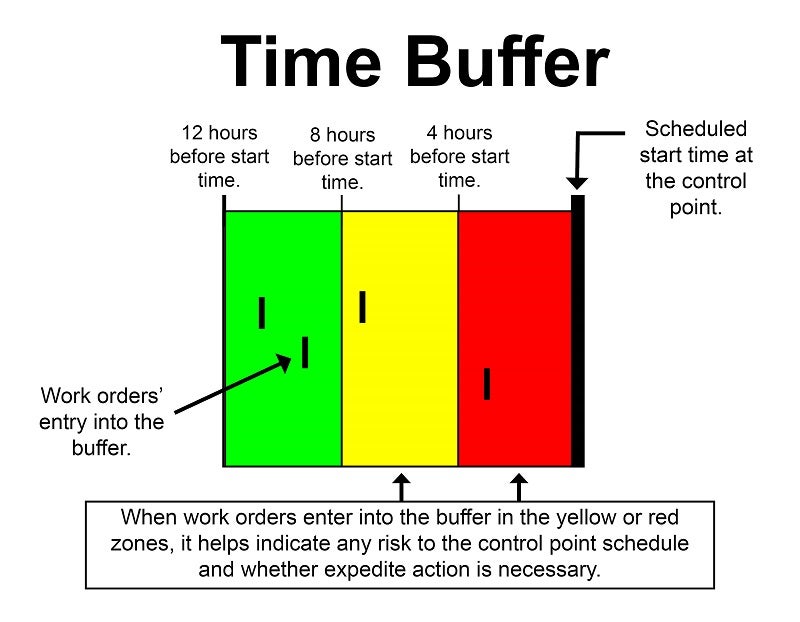

Time buffers work by scheduling a certain amount of time for work orders to be in the buffer before their scheduled start time at the control point. That scheduled amount of time between work orders’ entry to the buffer and their scheduled start at the control point should be divided into a green, yellow, and red zone, with red being closest to the scheduled start time at the control point. When work orders enter the buffer, their distance to the scheduled start time at the control point, and therefore their placement in the green, yellow, or red zone, will help indicate any risk to the control point schedule and whether expedite action is necessary.

Time buffers can be compared to setting multiple alarms for the morning. If you only get up at your last alarm (your "red zone") you will have to expedite your morning routine, whereas if you get up at your first alarm (your "green zone") you can follow your usual schedule/routine without worrying about being on time.